Como Escolher Matrizes de Peletizadoras para um Desempenho Ótimo na Peletização

2025-12-29

.gtr-pellet-dies-comp-9876 {

font-family: Verdana, Helvetica, "Times New Roman", Arial, sans-serif;

color: #333;

line-height: 1.6;

padding: 20px;

max-width: 100%;

box-sizing: border-box;

}

.gtr-pellet-dies-comp-9876 .gtr-title {

font-size: 18px;

font-weight: bold;

margin-bottom: 20px;

color: #0056b3;

text-align: left;

}

.gtr-pellet-dies-comp-9876 .gtr-section-title {

font-size: 18px;

font-weight: bold;

margin-top: 30px;

margin-bottom: 15px;

color: #0056b3;

text-align: left;

border-bottom: 1px solid #eee;

padding-bottom: 5px;

}

.gtr-pellet-dies-comp-9876 p {

font-size: 14px;

margin-bottom: 15px;

text-align: left !important;

word-break: normal;

overflow-wrap: normal;

}

.gtr-pellet-dies-comp-9876 p strong {

color: #0056b3;

}

.gtr-pellet-dies-comp-9876 ul {

list-style: none !important;

padding-left: 20px !important;

margin-bottom: 15px;

}

.gtr-pellet-dies-comp-9876 ul li {

position: relative;

padding-left: 20px;

margin-bottom: 8px;

font-size: 14px;

text-align: left;

list-style: none !important;

}

.gtr-pellet-dies-comp-9876 ul li::before {

content: "•" !important;

position: absolute !important;

left: 0 !important;

color: #0056b3;

font-size: 18px;

line-height: 1;

top: 0;

}

.gtr-pellet-dies-comp-9876 ul li strong {

color: #0056b3;

list-style: none !important;

}

.gtr-pellet-dies-comp-9876 .gtr-contact-info {

font-size: 14px;

margin-top: 20px;

text-align: left !important;

}

.gtr-pellet-dies-comp-9876 .gtr-contact-info a {

color: #0056b3;

text-decoration: none;

}

.gtr-pellet-dies-comp-9876 .gtr-contact-info a:hover {

text-decoration: underline;

}

@media (min-width: 768px) {

.gtr-pellet-dies-comp-9876 {

padding: 30px 40px;

max-width: 900px;

margin: 0 auto;

}

.gtr-pellet-dies-comp-9876 .gtr-title {

font-size: 18px;

margin-bottom: 25px;

}

.gtr-pellet-dies-comp-9876 .gtr-section-title {

font-size: 18px;

margin-top: 40px;

margin-bottom: 20px;

}

.gtr-pellet-dies-comp-9876 p {

margin-bottom: 20px;

}

.gtr-pellet-dies-comp-9876 ul {

padding-left: 25px !important;

}

.gtr-pellet-dies-comp-9876 ul li {

padding-left: 25px;

margin-bottom: 10px;

}

.gtr-pellet-dies-comp-9876 ul li::before {

font-size: 20px;

}

}

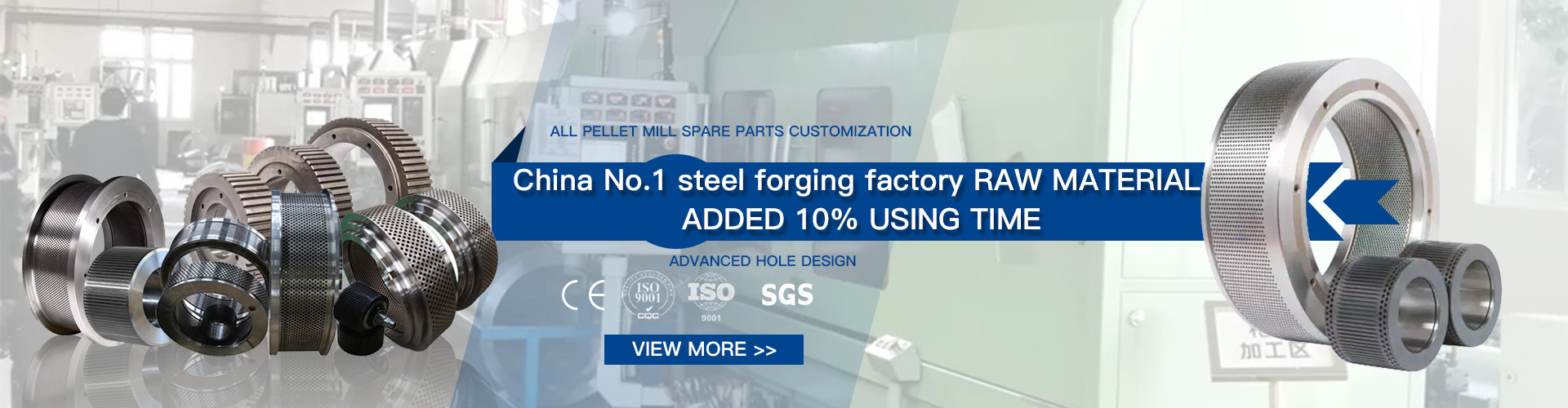

Moinho de pellets de alta qualidade para ótimo desempenho de peletização

Como um dos principais fabricantes de matrizes de moinho de pellets de alto desempenho, especializamo-nos na produção de matrizes de pellets personalizadas e padrão compatíveis com as principais marcas de moinhos de pellets, incluindo CPM, SZLH, PTN, Bühler,e maisQuer estejam envolvidos na alimentação animal, biomassa ou produção de fertilizantes orgânicos, os nossos matrizes de pellets são projetados para oferecer máxima eficiência, durabilidade e consistência.

O que é uma matriz de moinho de pellets?

A matriz de moagem de pelotas é um componente crítico no processo de pelletização.com um diâmetro superior a 30 mm,A matriz trabalha em conjunto com os rolos para aplicar pressão e calor, formando pellets compactos e densos ideais para transporte, armazenamento e alimentação.

Nossas capacidades para a matriz de pellets

Estamos equipados para fabricar matrizes com especificações exatas, garantindo a melhor compatibilidade e desempenho.

Fabricação sob medida (com base em desenhos ou amostras)

Matrizes padrão para os principais modelos de moinhos de pellets

Seleção de materiais (por exemplo, aço inoxidável, aço ligado)

Tamanhos dos furos de 1,0 mm a 12,0 mm

Relações de compressão adaptadas à sua matéria-prima e aplicação

Marcas compatíveis de moinhos de pellets

Produzimos moldes de substituição e personalizados para uma ampla gama de modelos de moinhos de pellets, incluindo:

CPM

SZLH

PTN

Bühler

E outras marcas internacionais populares

Todas as matrizes são totalmente testadas e inspecionadas para precisão dimensional, dureza e acabamento da superfície.

Por Que Escolher Nossa Matriz de Pellet?

Engenharia de precisão: matrizes usinadas por CNC garantem alta produção e qualidade consistente de pellets.

Soluções personalizadas: Relações de compressão e materiais adaptados para diferentes matérias-primas (milho, alfafa, farelo de trigo, etc.).

Longo Período de Utilização: Feito de materiais resistentes ao desgaste e tratados termicamente para durabilidade.

Entrega rápida: Produção e logística eficientes para entrega pontual em todo o mundo.

Apoio técnico: consultoria de peritos para a selecção da matriz e otimização da fábrica de pellets.

Aplicações

As nossas matrizes de pellets são amplamente utilizadas em:

Produção de alimentos para animais (aves, aves de capoeira, ovinos, peixes)

Biomassa Pelletização (madeira, palha, casca de arroz, etc.)

Pellets de fertilizantes orgânicos

Pelletização de resíduos industriais e agrícolas

Contacte-nos hoje

Procurando matrizes de moagem de grânulos confiáveis e de alto desempenho, faça parceria conosco para soluções personalizadas e qualidade imbatível.e vamos produzir uma matriz que se encaixa perfeitamente nas suas necessidades.

Email:Apexbiomass0909@gmail.comTelefone: [Way/line: +86- 18562307530]

Vista mais

Perspectivas globais do mercado da indústria de máquinas de moagem de pellets de biomassa

2025-12-24

.gtr-container-x7y2z9 {

font-family: Verdana, Helvetica, "Times New Roman", Arial, sans-serif;

color: #333;

line-height: 1.6;

padding: 15px;

box-sizing: border-box;

width: 100%;

max-width: 100%;

overflow-x: hidden;

}

.gtr-container-x7y2z9-title {

font-size: 18px;

font-weight: bold;

margin-bottom: 20px;

text-align: left;

color: #0056b3;

}

.gtr-container-x7y2z9 p {

font-size: 14px;

margin-bottom: 15px;

text-align: left !important;

line-height: 1.6;

color: #444;

}

.gtr-container-x7y2z9 p:last-child {

margin-bottom: 0;

}

.gtr-container-x7y2z9 strong {

font-weight: bold;

color: #000;

}

@media (min-width: 768px) {

.gtr-container-x7y2z9 {

padding: 30px;

}

.gtr-container-x7y2z9-title {

margin-bottom: 25px;

}

.gtr-container-x7y2z9 p {

margin-bottom: 20px;

}

}

Perspectiva do Mercado Global para a Indústria de Máquinas de Pelotização de Biomassa

O mercado global para Máquinas de Pelotização de Biomassa está a experimentar um crescimento constante, impulsionado por políticas de energia renovável e pelo aumento dos custos de energia. A Europa continua a ser a maior região consumidora de pellets, enquanto os mercados da América do Norte e da Ásia-Pacífico estão a expandir-se rapidamente.

As fábricas de pellets orientadas para a exportação dependem de Máquinas de Pelotização de Biomassa de alta capacidade para atender aos padrões internacionais de qualidade. A durabilidade dos pellets, o teor de humidade e a consistência do tamanho são fatores críticos para o comércio global.

Os fabricantes estão a oferecer cada vez mais soluções personalizadas com base no tipo de matéria-prima, capacidade de produção e regulamentos energéticos locais. Esta flexibilidade torna o equipamento de pellets de biomassa adaptável às diversas necessidades do mercado.

À medida que os investimentos em energia renovável aumentam em todo o mundo, espera-se que a Máquina de Pelotização de Biomassa continue a ser uma tecnologia chave que apoia a produção de energia sustentável e a proteção ambiental.

Vista mais

As máquinas de moagem de pellets a biomassa apoiam a crescente procura de combustível limpo para aquecimento

2025-12-24

As máquinas de moagem de pellets a biomassa apoiam a crescente procura de combustível limpo para aquecimento

A procura de combustíveis limpos para aquecimento continua a aumentar, nomeadamente na Europa e na América do Norte.Máquina de moagem de pellets a partir de biomassadesempenha um papel central na satisfação desta procura, permitindo a produção de pellets em grande escala.

Os pellets de biomassa são amplamente utilizados em fogões de pellets residenciais, sistemas de aquecimento urbano e caldeiras industriais.O seu tamanho constante e a sua elevada densidade permitem uma alimentação automatizada e uma combustão eficiente.

Os moinhos de pellets concebidos para uso industrial podem funcionar 24 horas por dia, 7 dias por semana, com tempo de inatividade mínimo.Equipamentos de triagem de pellets são muitas vezes integrados em linhas de produção completas.

Com restrições crescentes no uso de carvão e combustíveis fósseis, os pellets de biomassa estão a tornar-se uma alternativa preferida.O investimento em máquinas de moagem de pellets de biomassa continua a crescer nos mercados mundiais.

Vista mais

Os avanços tecnológicos melhoram a eficiência das máquinas de moagem de pellets a partir de biomassa

2025-12-24

Avanços Tecnológicos Melhoram a Eficiência das Máquinas de Pelotização de Biomassa

A inovação contínua melhorou significativamente o desempenho da Máquina de Pelotização de Biomassa nos últimos anos. Os fabricantes agora se concentram em aumentar a produção, reduzir o consumo de energia e prolongar a vida útil dos equipamentos.

Um avanço importante é o uso de aço de liga de alta resistência para matrizes e rolos. Isso melhora a resistência ao desgaste e permite que as máquinas operem sob cargas pesadas por períodos prolongados. Sistemas de lubrificação automática reduzem ainda mais os requisitos de manutenção.

Sistemas de controle inteligentes também se tornaram padrão. Os operadores podem monitorar a temperatura, pressão e carga do motor em tempo real, garantindo uma operação estável e qualidade consistente dos pellets. Esses sistemas reduzem o tempo de inatividade e melhoram a eficiência geral da produção.

A eficiência energética é outra melhoria fundamental. Sistemas de transmissão otimizados e acionamentos de frequência variável ajudam a reduzir o consumo de energia por tonelada de pellets produzidos.

Graças a essas inovações, as Máquinas de Pelotização de Biomassa são agora mais confiáveis e econômicas, tornando-as adequadas tanto para grandes plantas industriais quanto para operações de biomassa de médio porte.

Vista mais

Por que as Máquinas de Pelotização de Biomassa são Essenciais para a Reciclagem de Resíduos Agrícolas

2025-12-24

Por que as Máquinas de Pelotização de Biomassa são Essenciais para a Reciclagem de Resíduos Agrícolas

A gestão de resíduos agrícolas tornou-se um grande desafio em todo o mundo. A Máquina de Pelotização de Biomassa oferece uma solução eficaz, transformando resíduos de culturas em combustível renovável valioso.

Materiais como caules de milho, palha de trigo, cascas de arroz e cascas de girassol são frequentemente descartados ou queimados em campos abertos. Ao usar uma Máquina de Pelotização de Biomassa, esses materiais podem ser processados em pellets de biomassa adequados para aquecimento industrial e residencial.

O processo de pelotização reduz o volume do material, aumentando a densidade energética. Isso torna o transporte e o armazenamento mais eficientes e reduz a poluição ambiental. Agricultores e processadores de biomassa também podem gerar renda adicional convertendo resíduos em produtos comercializáveis.

Máquinas de Pelotização de Biomassa avançadas são projetadas para lidar com teor de umidade variável e matérias-primas mistas. Rolos reforçados e designs de matriz otimizados garantem a formação estável de pellets, mesmo ao processar biomassa agrícola desafiadora.

Com o crescente interesse em modelos de economia circular, a produção de pellets de biomassa está se tornando um elo importante entre a agricultura e as indústrias de energia renovável.

Vista mais